6. Expertise & Related Equipment

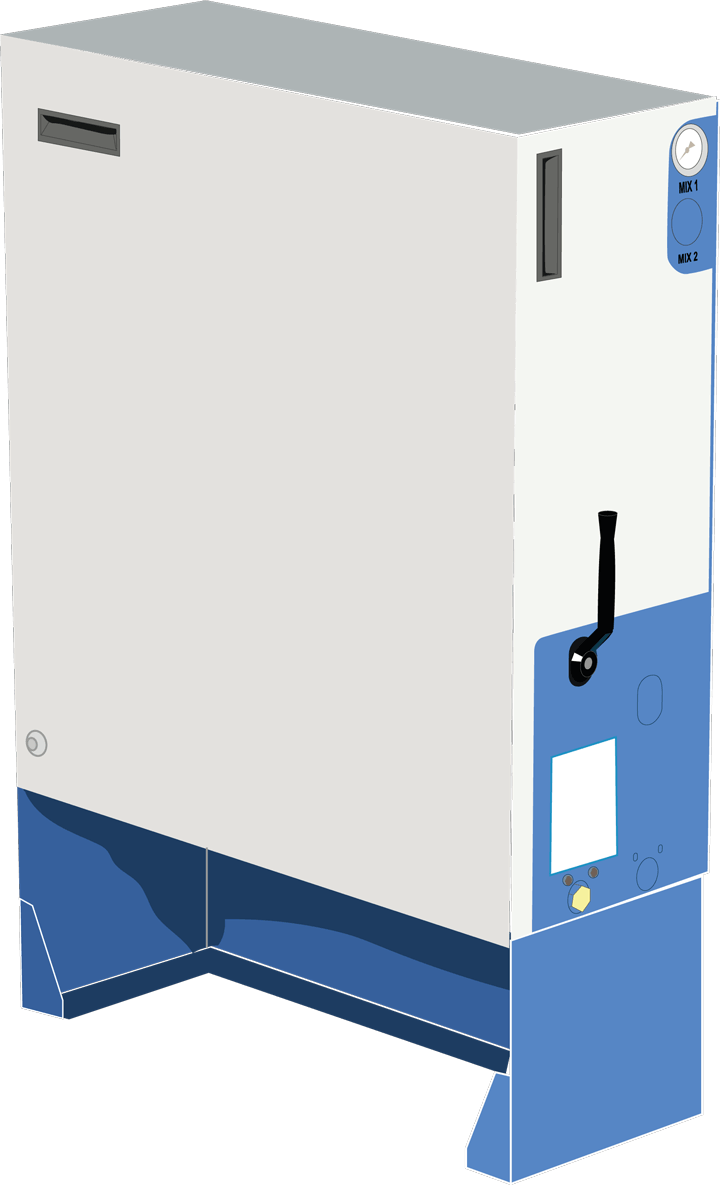

6.4 Dynamic On-site Mixer

Simply high performance

In addition to the gas cylinder and rack supplies, Air Liquide also offers ARCAL™ and ALIGAL™ gas solutions in bulk supply for customer that require a larger quantity of welding gas. The Dynamic On-site Mixer (D.O.M) maintains the quality and reliability of the gas to deliver a consistent welding arc every time and expected performance under any flow conditions.

Simplicity

- Proprietary Air Liquide upgrade of a commercial mixer with turn-key integration of all peripherals.

- No electrical connection, solenoid valve, nor buffer tank required.

Standardised Models

- mono mix with one fixed gas composition.

- Dual-mix with two inputs on different fixed gas compositions.

- 50 m3/h and 100 m3/h max flow rate.

- Mini-DOM: 1x 900, 1x 900 + 1x 1800, 1x 2700, 3x 900

- Regulated Argon available on some models.

Performance

- High accuracy of mix at any welding flow rate: Compliant to AWS 5.32 / ISO 14175.

- Outlet pressure from ~2 to 90 psi (inlet must be > 175 psi to get 90 psi outlet).

6. Expertise & Related Equipment

6.5 FLOXAL™

On-site Generators Solution

We offer high quality on-site generators under FLOXAL™, available for: Nitrogen, Oxygen and Hydrogen. For each molecule, various generation technologies are used to ensure customers' satisfaction at a competitive price. The installation, operation and maintenance, telemonitored performance tracking and full back-up are included in our services.

FLOXAL™ fits the needs of customers of various market segments such as Materials, Energy, Food, Pharmaceutical, Automotive, Fabrication, Technology, Research, and applications. The customers needs:

- O₂, N₂, H₂ in gaseous phase, purity can be produced by generators.

- Relatively high level of demand (lower costs than bulk), best supplied by a dedicated generator.

- Continuous operation, stable flow rate, allowing the generator to run continuously at the highest utilisation rate.

- Needs uninterrupted supply of gas with full back-up, even during utility failure.

- Needs dedicated local production to minimise transportation risks.

- Minimise cost with a more optimised investment, efficient energy consumption and reduced carbon footprint.