6. Related Equipment & Services

6.8 ECO CHILLER

ECO CHILLER is an automated heat exchanger equipment designed by Air Liquide to improve the efficiency of customers' cooling process. The system works by recycling the cold generated by the vaporisation of Liquid Nitrogen, Liquid Oxygen or Liquide CO2, back into customers' cooling system and conveniently plugs into the water-cooling network. ECO CHILLER is best suited for liquid gas consumption starting from 50 m3.

| ECO CHILLER | 100 | 300 | 600 |

|---|---|---|---|

ECO CHILLER Flow Rate (Nm 3/h) |

100 100 |

300 300 |

600 600 |

ECO CHILLER Weight (kg) |

100 300 |

300 500 |

600 700 |

ECO CHILLER Length (m) |

100 2.8 |

||

ECO CHILLER Depth (m) |

100 2.2 |

||

ECO CHILLER Height (m) |

100 1.9 |

||

Note : Estimated weight to be validated based on actual requirement. Customisation is also available based on actual gas consumption

ECO CHILLER helps users to lower environmental impact by reducing their footprint. The system makes a valuable contribution to achieving ISO 50001 and ISO 14001 certifications.

- Constant gaseous Nitrogen (N2) gas temperature.

- Avoid icing and fog.

- Thanks to the evaporation process you are able to rely on a more constant temperature.

- At the same time, icing and fog formation related, decreases, thus improving your safety process security.

- Significant reduction of energy costs while recycling the cool generated by

vaporisation.

6. Expertise & Related Equipment

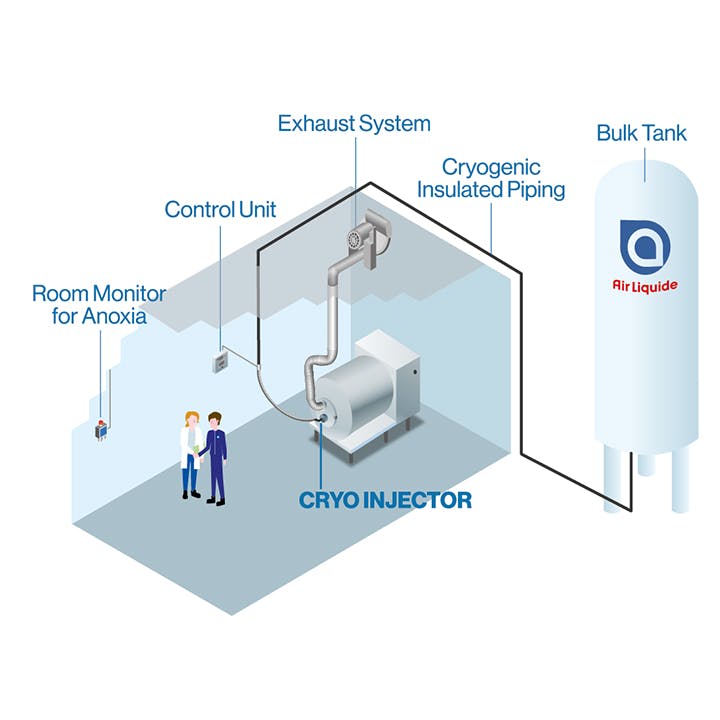

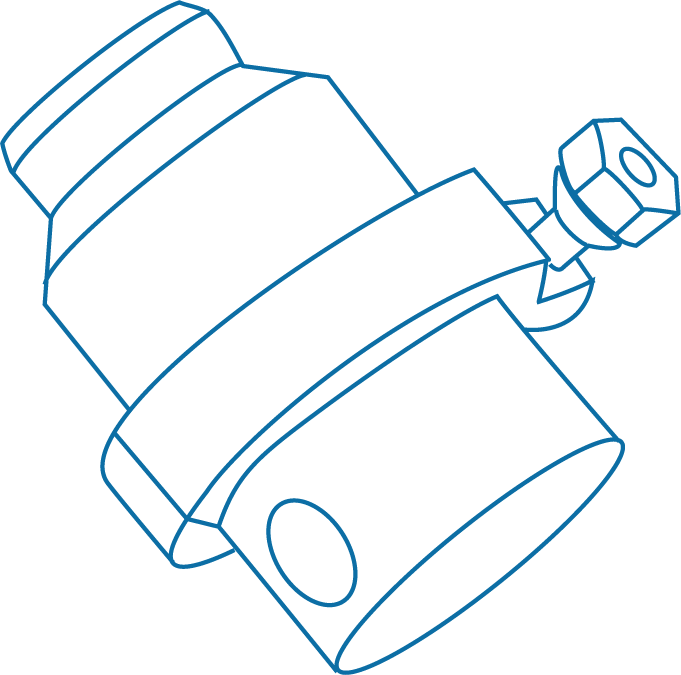

6.9 CRYO INJECTOR-CB3

The CRYO INJECTOR- CB3 stainless steel cryogenic injector designed by Air Liquide for bottom injection temperature control applications. The CRYO INJECTOR- CB3 is ideal for the temperature control and chilling of many types of food products. It offers the versatility to efficiently chill and control the temperature, while ensuring exceptional product quality.

The benefits :

- Flexibility to chill and control the temperature of different types of food products during the mixing, grinding or blending operations

- Accurate and consistent temperature control over a wide temperature range

- Faster chilling times than many open-ended types of injectors

- Self-sealing design prevents food blockage in the injector

- Improved cryogen efficiency by up to 50% over top injection

- Minimal capital investment and installation cost

- Safe and easy to install and operate

- Minimal maintenance required

- Stainless steel construction

- Easily dismantled & reassembled for cleaning operations