2. Supply Mode

2.4 Packaged Gas

For gas users who need mobility and/or with demand for small volumes, gas cylinders can represent an extremely practical method of supplying gas to meet the needs of various manufacturing processes. The gases can be supplied in either individual cylinders or racks of various capacities for your application and delivered promptly to the doorstep by our transport fleet. We ensure full compliance with IMS requirements to ensure safety and quality in our products.

For users who have a gas volume requirement of less than 5,000m³ per month, we offer many types of packaged gases and gas mixtures in various capacities for an extensive array of applications.

2.4.1 Cylinder

Air Liquide designs and produces the market’s safest, most ergonomic, user-friendly cylinders, and valves for small, medium, and mobile gas needs. Best-fit solutions for your application with Air Liquide's premium offers.

Our cylinders can come with the safest and most ergonomic valves:

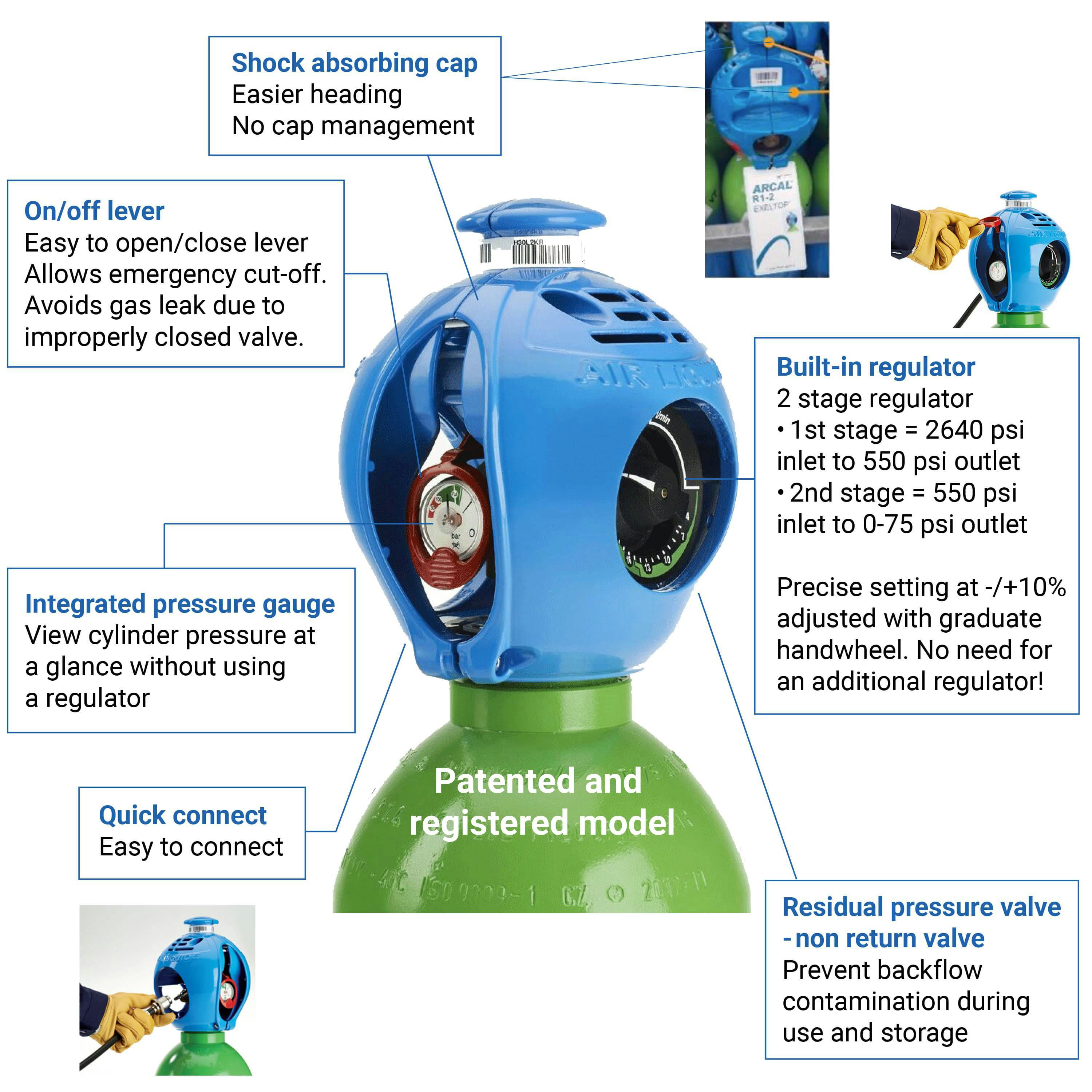

EXELTOP™

A new generation cylinder valve with built-in pressure regulator, available with our premium gases ARCAL™ shielding gases and FLAMAL™ oxy-fuel gases for welding and cutting applications.

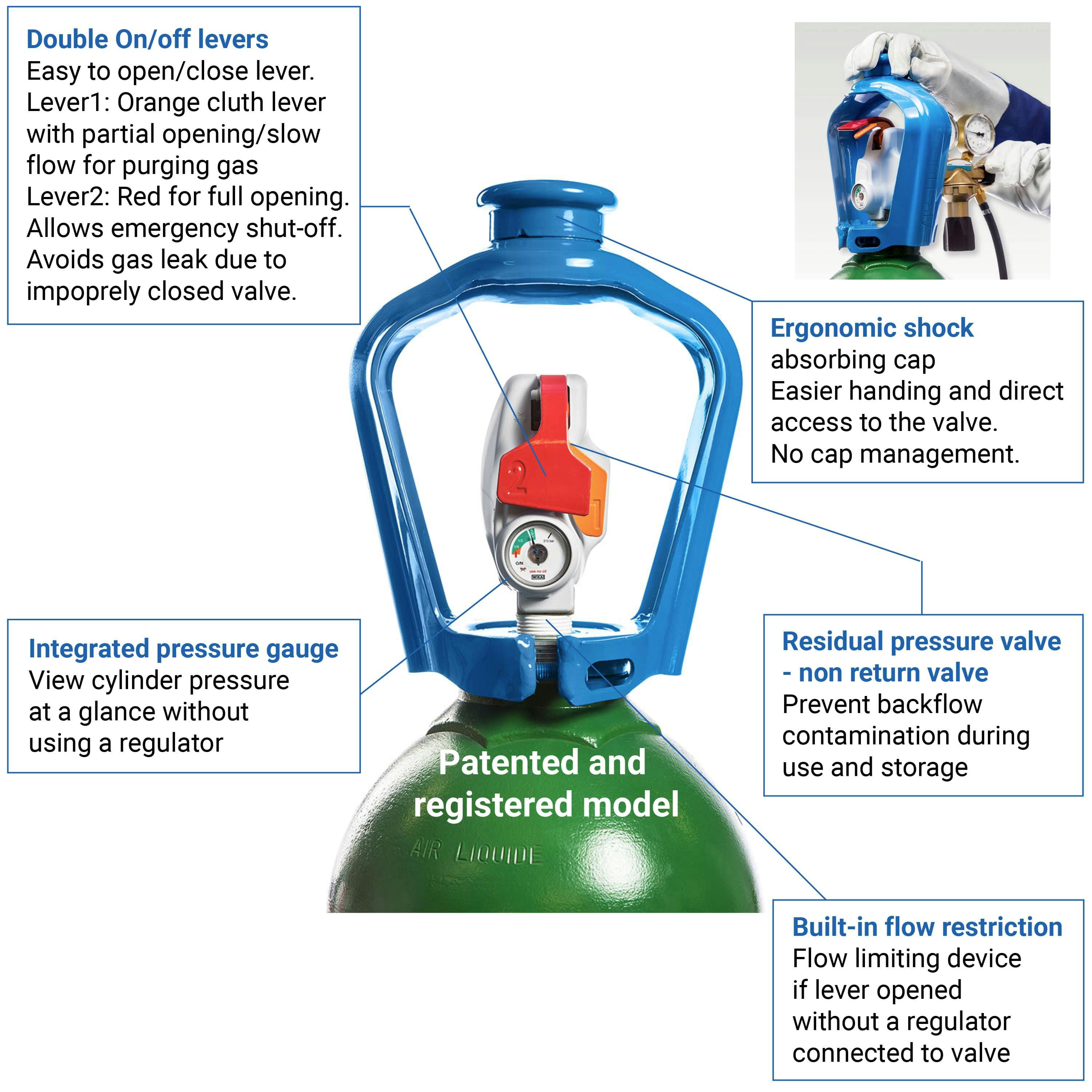

SMARTOP™

A cutting edge smart residual pressure valve with an on/off lever and permanent content gauge, available with our ALPHAGAZ™ pure gases premium offers for analytical applications.

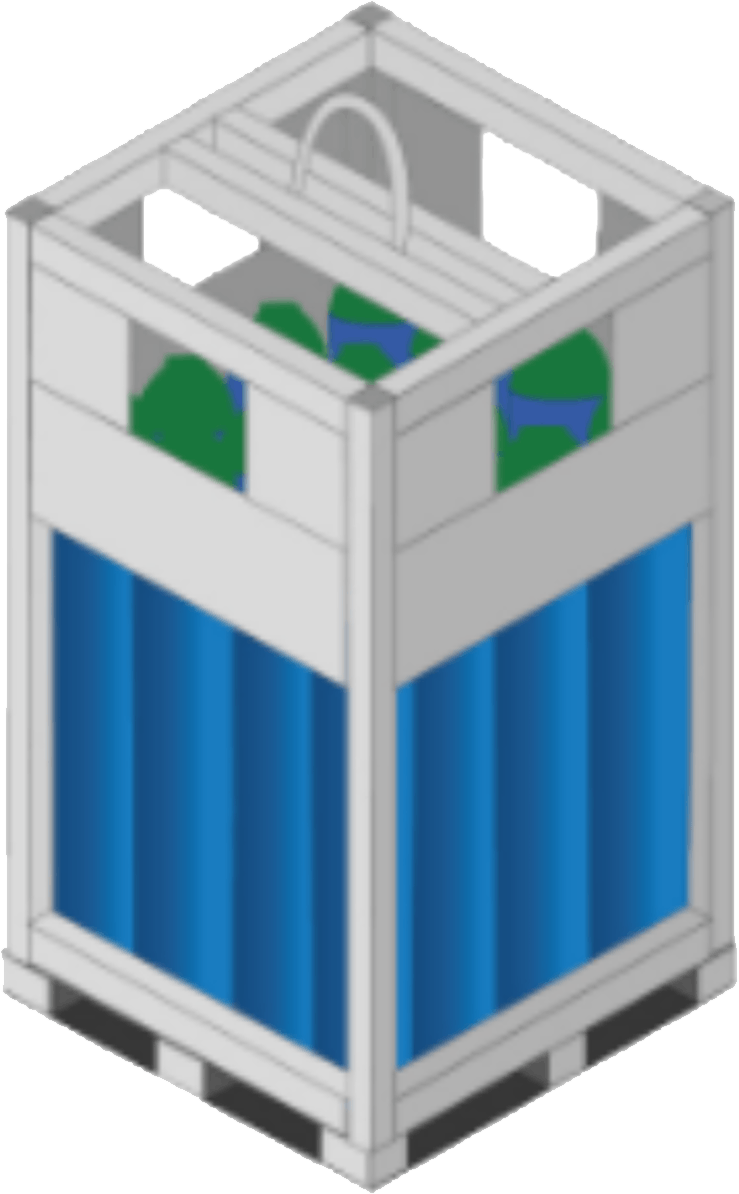

2.4.2 Cylinder Rack

For applications that require higher capacities, a cylinder rack is a viable solution. Depending on the size of the basket, cylinder pallets consist of 6 to 16 cylinders in bundles with gas outlets. The benefits of the cylinder rack :

Continuity

With higher autonomy, the cylinder rack provides higher volumes of gas supply ensuring longer continuity in usage.

Convenience

Customers do not need to change cylinders as frequently as compared to individual cylinders and therefore provides less handling effort.

Safety

Cylinders that are bundled in a rack are more robust. Their stability and mobility make them well-suited to the shipyard and construction industries.

To accommodate higher needs, the gases can be readily compressed up to 300 bar pressure. Our 300 bar rack is an innovative supply mode that provides a higher volume of gas with mobility requirements for the project use.

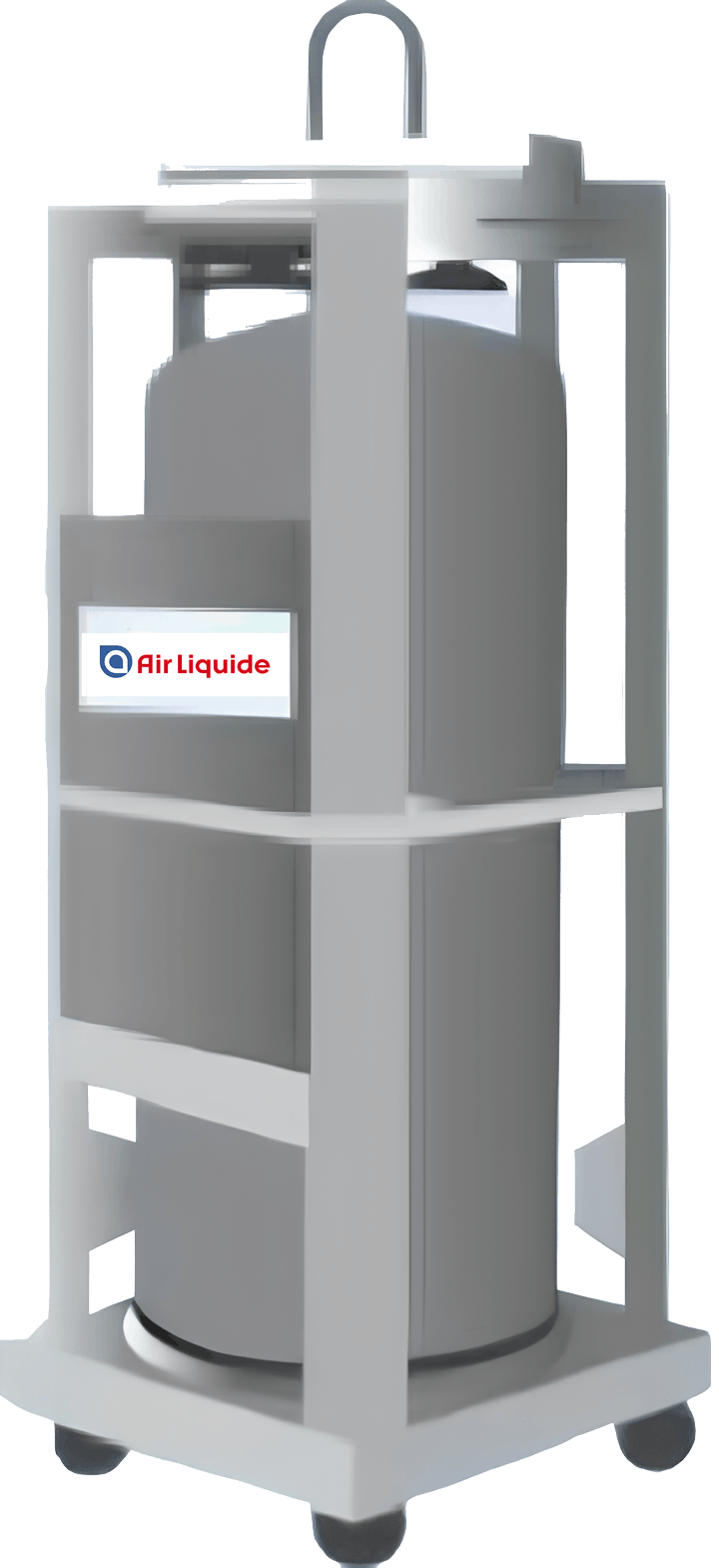

2.4.3 Liquid Gas Cylinder (LGC)

An LGC is a portable super-insulated vacuum vessel holding Liquid Argon, Carbon Dioxide, Nitrogen and Oxygen. LGC is normally supplied as an intermediate gas system between vacuum insulated evaporator (VIE) tanks and cylinders which can be used individually or in conjunction with a manifold system.

| Specifications | ||

|---|---|---|

| Materials |

Inner Vessel |

Stainless steel |

|

Insulation |

Multiple layer wrapped with high vacuum super insulation |

|

|

Outer Shell |

Carbon steel / stainless steel | |

| Gas Withdrawal |

Flow Rate

|

9 m³ / hour continuous (Oxygen, Nitrogen, or Argon) without external vaporiser |

|

Boil Off Rate |

Maximum (with Liquid Nitrogen) 2.2% per day |

|

| Model | XL-45 H | 200 L MP |

|---|---|---|

| Dimensions LGC | Dimensions LGC XL-45 H 51 cm x 153 cm |

Dimensions LGC 200 L MP 51 cm x 167 cm |

| Water Capacity | Water Capacity XL-45 H 165 L |

Water Capacity 200 L MP 196 L |

| Weight (with Trolley, empty) | Weight (with Trolley, empty) XL-45 H 125 kg |

Weight (with Trolley, empty) 200 L MP 127 kg |

| Relief Valve Setting | Relief Valve Setting XL-45 H 24 bar |

Relief Valve Setting 200 L MP 16 bar |

| Valve Outlet Connection | Valve Outlet Connection XL-45 H 3⁄8” FNPT |

Valve Outlet Connection 200 L MP 3⁄8” FNPT |