2. Supply Mode

2.3 Bulk

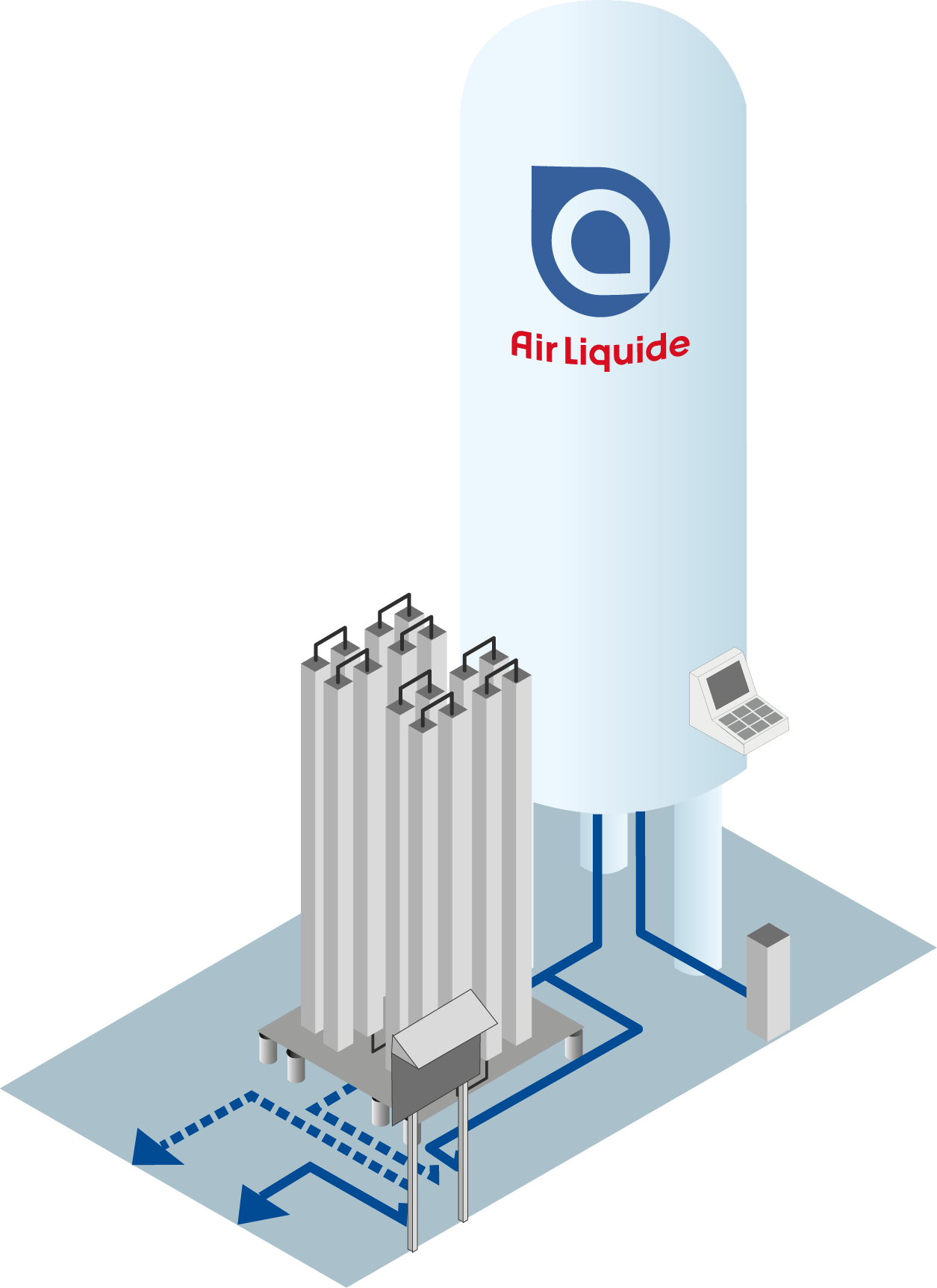

If your operations require a large steady flow of gases (exceeding 100,000m3 per month), our bulk distribution and storage solutions will meet your needs. We offer safe and reliable industrial-grade bulk products (Oxygen, Nitrogen, Argon, and Hydrogen) which are produced and liquefied in our plants and delivered directly to customers’ cryogenic liquid storage vessel by insulated cryogenic trucks. Our expertise extends to the installation, maintenance and monitoring of liquefied gas storage systems. We offer safe and reliable bulk systems, with a robust supply chain, that enable us to deliver in a range of sizes and flow capacities which meet the needs of many industries.

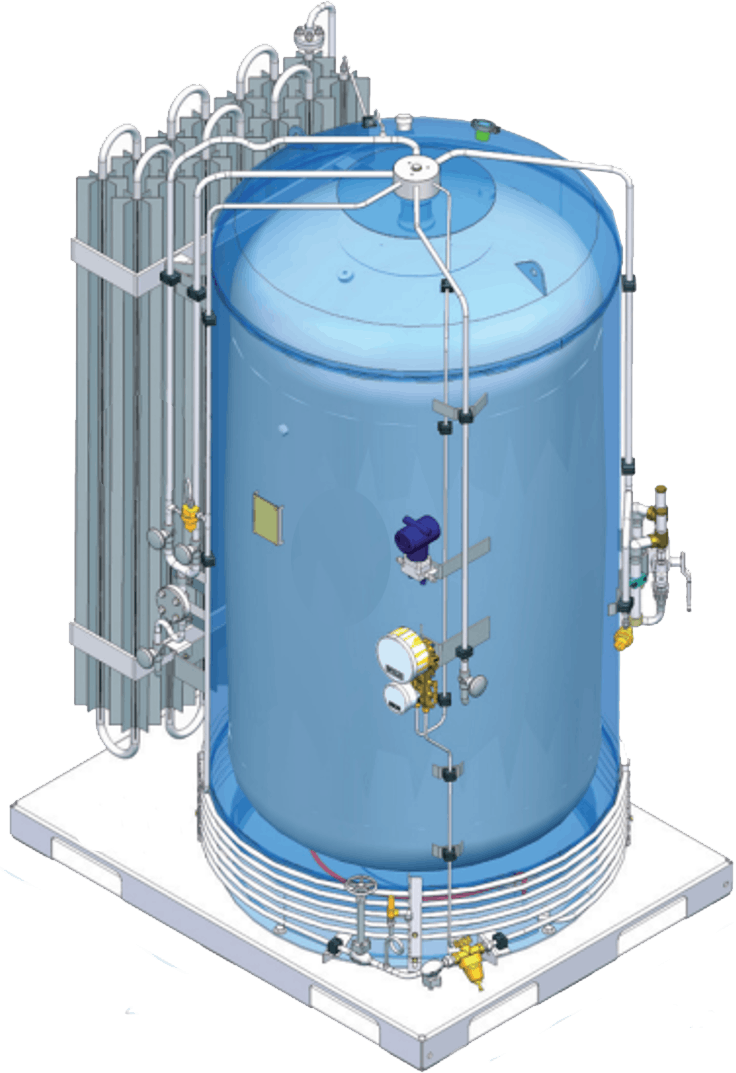

2.3.1 Cryogenic Storage Tank

Cryogenic Storage Tanks are designed primarily for the storage and distribution of liquefied gasses, such as Liquid Argon, Liquid Nitrogen and Liquid Oxygen. It is a compact, self-contained automatic system which serves as a central supply of gas into a customer's piping system. Gases are stored at our production facilities in liquid phase and delivered directly to our customer in insulated cryogenic tanks. The product can either be withdrawn as a liquid or vaporized into the local distribution system in its gaseous form.

| Specifications | ||

|---|---|---|

| Tank Capacity | 6,000 L to 50,000 L | |

| Pressure | Up to 35 barg | |

| Flow Rate | Up to 500 Nm3 per hour | |

| Usage | Gaseous or cryogenic liquid | |

2.3.2 Micro Bulk

The Micro Bulk offer is an all-in-one air gas cryogenic vessel with an integrated storage and supply system. The Micro Bulk offer fits in the customer profile with high pallet usage at a fixed gas usage point, ranging from 500 m3 to 10,000 m3 per month. The Micro Bulk storage system is able to accommodate pressure requirements of up to 450 psi. Air Liquide delivers the liquid safely, conveniently and effectively via dedicated Cryo Service trucks.

Micro Bulk solutions are ideal for businesses with growing demands for industrial gases. Conversion from cylinder to Micro Bulk supply will simplify your operations as follows:

- Reduce gas handling

- No more lost or damaged cylinders

- Minimise the risk of gas stock disruption

- No more cylinder changeouts

- Save costs due to lower residual gas loss

- No civil works required, simplifying permitting and saving space.

| Tank Specification | ||

|---|---|---|

| Tank Capacity | 1,000 L to 5,000 L | |

| Pressure | Max 450 psi or 35 Bar | |

| Operating Pressure | From 1 to 32 barg | |

| Flow Rate | Maximum 100m3 / hour | |

| Usage | Gaseous or cryogenic liquid | |