ENERGY TRANSITION

An electrolyzer to accelerate the decarbonization of German industry

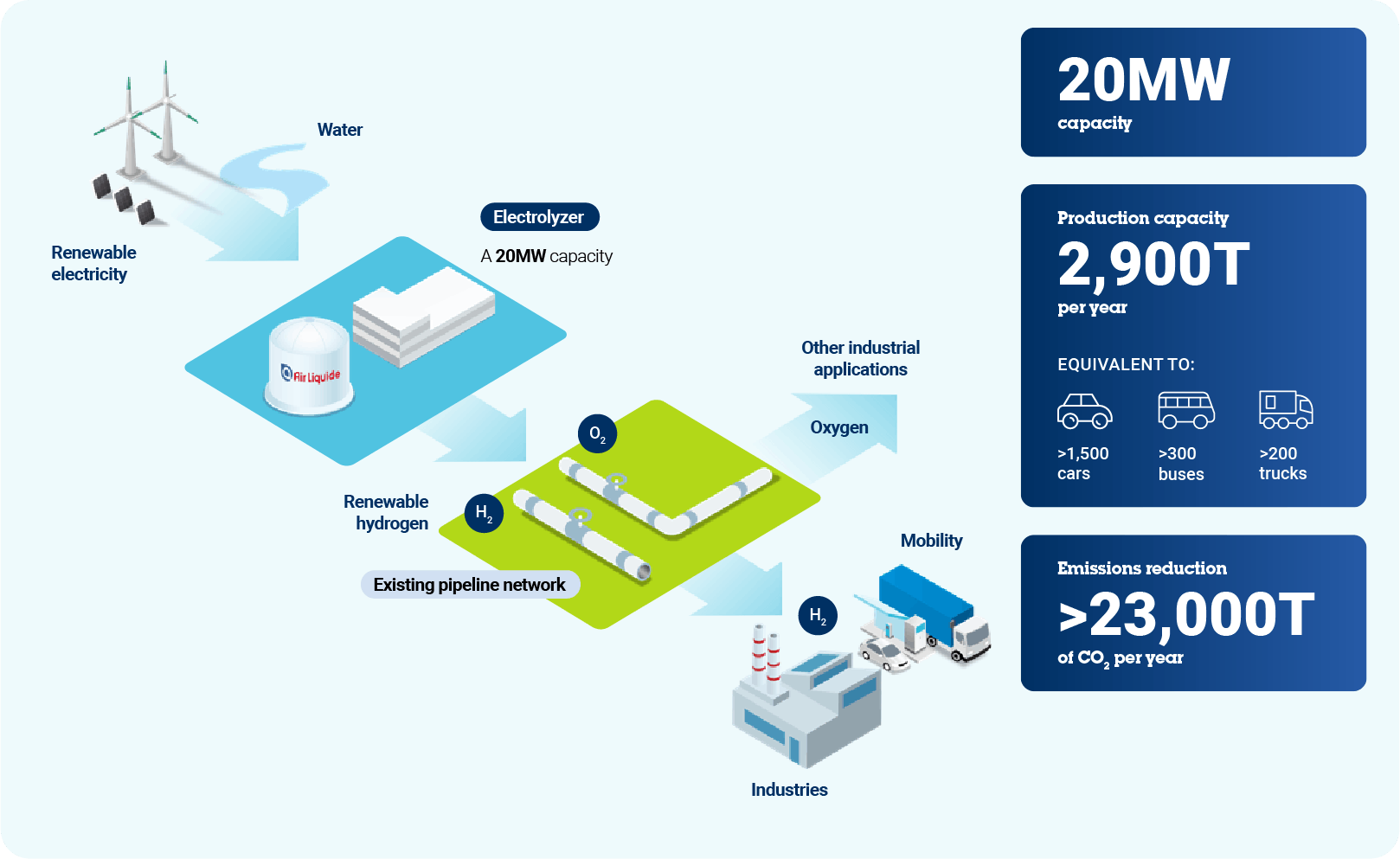

In 2024, Air Liquide launched a 20MW electrolyzer to produce renewable hydrogen in Oberhausen, Germany. The electrolyzer, which is now connected to Air Liquide’s pipeline network, is gradually supplying hydrogen to local industrial and mobility customers. This project represents a big step forward in decarbonizing the Rhine-Rhur industrial basin. It also demonstrates the power of the collective drive to develop the hydrogen industry, which is being undertaken notably in partnership with Siemens Energy and with the backing of the German government.

This image is dedicated to the low-carbon electrolysis project in Oberhausen, the heart of the Rhine-Ruhr industrial basin, with a focus on renewable hydrogen.

Infrastructure

Input :

- Renewable electricity (wind and solar)

- Water

Electrolysis : 20 MW electrolyzer

Product:

- Renewable hydrogen (H₂)

- Oxygen (O₂)

- Hydrogen and oxygen uses Mobility (vehicles, buses, trucks)

- Industries (direct use of H₂)

- Other industrial applications (notably oxygen)

Key project figures

Installed capacity: 20 MW

Annual hydrogen production capacity: 2,900 tonnes

Mobility which is the equivalent of:

- More than 1,500 cars,

- More than 300 buses,

- More than 200 trucks.

- Reduction in CO₂ emissions: over 23,000 tonnes per year

Located in Oberhausen at the heart of Germany’s Rhine-Rhur industrial basin, the Proton Exchange Membrane (PEM) electrolyzer produces renewable hydrogen and oxygen from water and renewable electricity. Directly plugged to Air Liquide’s pipeline network, it is the largest electrolyzer in Germany to be connected to an existing infrastructure and is capable of producing up to 2,900 tons of hydrogen a year – equivalent to the annual consumption of 300 buses.

While it has received € 10.9 million in funding from the German Federal Ministry for the Economy and Climate Protection, the electrolyzer is also the fruit of a private partnership with Siemens Energy. The PEM modules used on the site were manufactured at the gigafactory built by Air Liquide and Siemens Energy in Berlin. By mass manufacturing electrolyzer components, this joint venture is paving the way for low-carbon and renewable hydrogen to be produced at an industrial scale and a competitive cost.

The new electrolyzer will accelerate the decarbonization of key industries in North Rhine-Westphalia and promote low-carbon mobility in this densely populated region. This shows what can be accomplished when authorities and corporations work together to achieve a common goal.

⟶Sylvie Villepontoux,

CEO of Air Liquide Central Europe Cluster